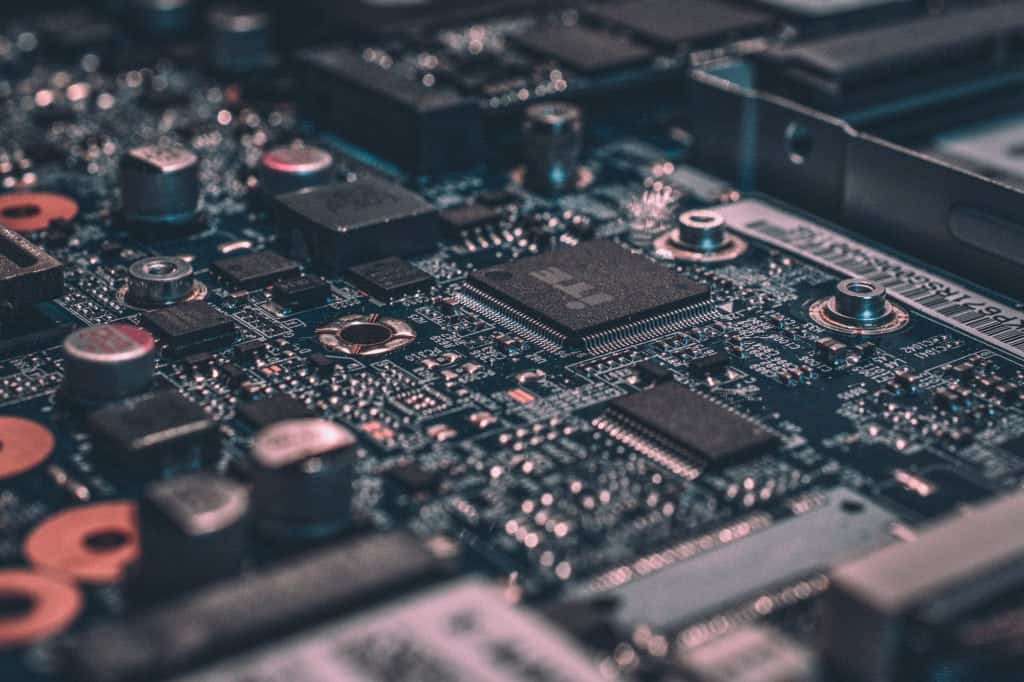

As the age of electronics continues to grow, more and more devices use sensors and updated components, and are exponentially becoming smarter. While this makes our everyday life easier, it’s also causing a shortage in these updated component parts. This shortage is quickly becoming a crisis as the demand rises, as the current supply becomes more limited and more components are needed and because of this just can’t be manufactured fast enough.

The Growth of Electronics

The most impacted components are the MLCC (multilayer ceramic capacitors), surface mount devices (SMD) and SMD resistors with semiconductors. Electronic component shortages are such an issue now that many OEMs are predicting their forecasted growth for 2018-2019 will be derailed if they’re unable to source out for the parts they need.

The evolution of the auto industry and the Internet of Things are some of the main factors that have contributed to a strong demand for more and more components. A combustion engine today can require approximately 3000 capacitors. Forecasters project that the number of MLCC in that one car could rise to 22000 in the near future.

Within the Internet of Things industry, more and more devices are becoming smart, including smart TVs, Bluetooth devices, cloud components, wearable technology, sports technology, and communications, etc. It’s estimated that these devices will grow to 31 billion worldwide within the next few years.

Sourcing Older Components

In some cases the issue isn’t new products, but maintaining and servicing the previous, older products. Many products are not replaced as soon as the new one comes out and they become obsolete. Therefore, there is a slight need for those obsolete parts, but generally not a large supply of them.

The longer a part has been replaced by a new one, the more likely it is that there will be many unscrupulous companies that will begin to counterfeit parts. Some companies are well meaning, in an attempt to lower the cost of repairs, while others, not so much.

In other cases there is just not such a huge demand for a particular part or component, but a necessary demand, nonetheless. Sometimes in a military application, there are a limited amount of specific parts or components. Manufactures will, therefore, not create a large amount of excess as stock for repairs in the future, as it’s an uncertainty when they will ever be needed, if they are ever needed.

Finding An EMS or CEM Manufacturing

During this shortage many OEMs are looking to find other component sourcing for their components, but they want EMS manufacturing they can trust. Finding an EMS manufacture that can design and manufacture a component may assist in reducing the lead time needed in some products or parts.

Some EMS manufactures have a wide range of services, ranging from design to manufacturing to complete ready-made products, which can assist a company in several ways. These are important factors when searching for a component source that is to become a part of the product you provide.

An EMS manufacturing company with a list of suppliers that they have used and which they may have a strong relationship with can be an important factor as well. If the manufacturer and the supplier have a strong relationship, they may also have some kinds of benefits or discounts which may be passed on to the OEM. This may, in turn, create a lasting relationship between the OEM and the EMS manufacturing company.

Certification

While there are over 1,000 EMS manufactures operating in Europe, the majority of them are small companies (under 10 million Euro) serving national markets. It’s important to know the quality certifications of an EMS manufacture.

An ISO 9001:2015 certification is the world’s most widely recognized quality management system. This certification ensures an increased business efficiency, a higher level of customer satisfaction, lower unnecessary costs and more reliable quality of processes and products. The other benefit for this certification is it’s qualification as a supplier for many customer contracts.

The issues caused by the Shortage

The shortage of component sourcing is synonymous with the shortage of components. As OEM manufacturing struggles to keep up with the components demand, EMS and CEM manufacturing also struggle.

The uncertainty that arises with the component shortage can make some wonder about their company viability. This becomes a problem when they are unable to produce the products they have previously forecast for the current year. This may also make some rethink where and how they manufacture their products.

To increase their production some OEM manufacturing companies have looked into the costs of updating their manufacturing. The cost of these updates, in most cases is not reasonable and would make them much less able to effectively compete.

The lead times for ordering component has extended out anywhere from 20 – 50+ weeks, resulting in delays to customers. This imbalance in supply has also lead to increased prices.

Possible solutions

But there are some possible solutions. Some EMS manufacturing companies are working with their customers ahead of time, planning in advance to forecast for demand. Others double their orders to avoid problems in the future.

Some EMS manufacturing companies are ordering from catalog distributors during the shortage.

Asking for help is not always a bad idea. While some EMS or CEM manufacturing companies only provide parts, others provide many other services, including design and procurement services.

Summary

The fact is that manufacturing just can’t keep up with the demand for the various components needed in our everyday lives. As more and more devices are created to make our lives easier, and as those devices become more sophisticated, demand increases. Therefore, component sourcing becomes an issue.

Finding the right EMS manufacturing or CEM manufacturing company to produce the components necessary for future devices as well as those that are already out in the market can become an arduous task. But it can be done. Sedgewall Ltd. has all the services you may need. They know the suppliers and have the necessary relationships with them to give you every advantage; and they have the needed manufacturing technology as well. They can help with design and then assist you with the creation of a prototype.

With planning and research you can find the right manufacturing company to fit your needs and to help with whatever you may need.